30 Seconds per Piece Ultra-High-Speed Printing

360° seamless spiral printing technology

Excellent Imaging Quality

Compatible with Various Materials, Easy Flexible Customization

Conquer 25mm Height Differences,Outstanding print quality even on uneven curved surfaces

Multi-Effect Synchronous Output: Color + White + Varnish Printed Simultaneously for Combined Visual and Tactile Impact

Wide Material Compatibility, Flexible Customization with Ease

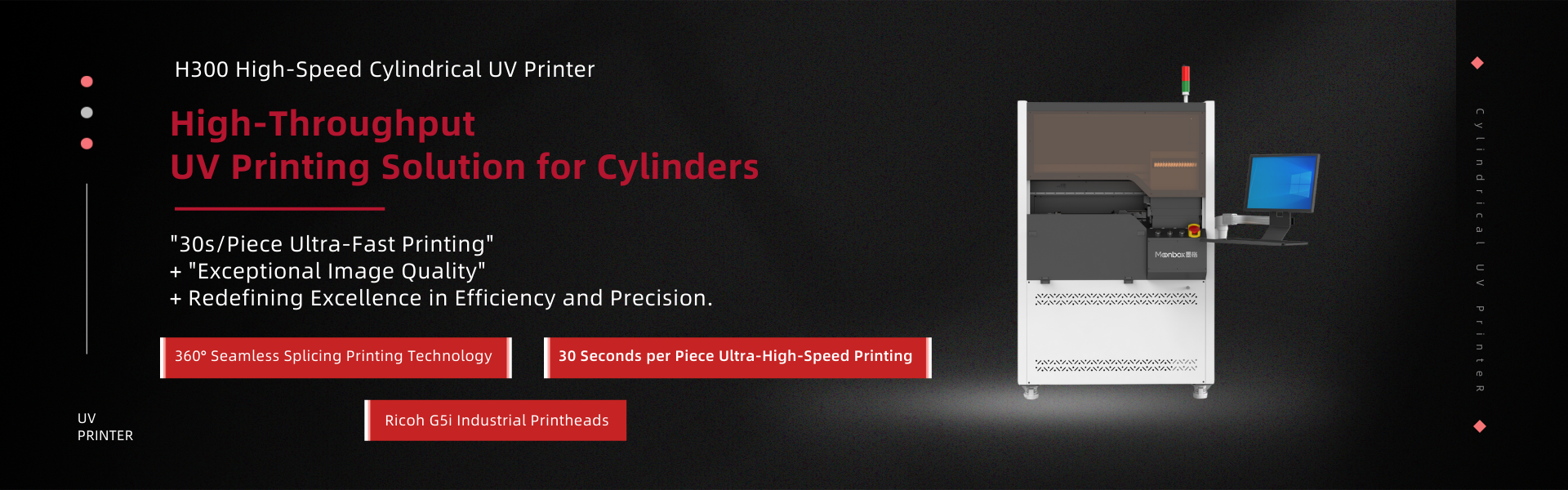

Moonbox H300 High-speed Cylinder UV Printer is specially designed for cylindrical and conical curved surfaces, integrating ultra-high-speed printing with excellent imaging quality. Equipped with industrial-grade piezoelectric printheads and a high-speed UV curing system, combined with high-precision servo control, the high speed UV printer enables efficient production at up to 30 seconds per piece. At the same time, it features high-precision printheads such as Ricoh G5i, supporting multi-level grayscale and high-resolution output. The result is delicate, saturated colors with rich, sharp details — truly balancing printing speed with superior image quality.

Step 1: Design the pattern on the computer.

Step 2: Place the item into the fixture and secure it.

Step 3: Start printing — the finished product can be ready within 30 seconds.

This technology integrates intelligent algorithms, precise mechanical control, and advanced printing processes to achieve seamless connection in curved-surface printing. During printing, the cylinder or cone rotates at a constant speed while the printhead moves synchronously along the axis, drawing with the precision of a fine “compass.” The system continuously monitors the rotation angle in real time, dynamically calibrating the pattern’s shape while precisely controlling the placement and timing of each ink droplet to ensure perfect synchronization throughout the process. As a result, the design seamlessly connects end to end, with no overlaps or misalignments, delivering a unified, high-quality 360° full-wrap printing effect.

Equipped with industrial-grade piezoelectric printheads and a high-speed UV curing system, combined with high-precision servo control and automated workflow, it ensures imaging quality while achieving a printing time as short as 30 seconds per piece, significantly boosting productivity.

Standard configuration with Ricoh G5i industrial printheads (supporting multiple optional printhead models), featuring high resolution and multi-level grayscale output. The high speed UV printer delivers smooth color transitions, sharp and rich details, and high image fidelity.

Equipped with an intelligent curved-surface printing system, the high speed UV printer can sense and scan the object's surface in real time. Based on the structural features of cylindrical, conical, or irregular curved surfaces, it intelligently adjusts the printhead height, spray angle, and ink volume. Even on embossed surfaces with height differences of up to 15mm, this commercial UV printer still achieves high-definition, uniform, and blind-spot-free printing, fully supporting high-quality printing on complex curved surfaces.

Supports synchronous output of CMYK + white ink + 3D varnish, enabling the integration of color, dimensionality, and special effects in a single pass. By precisely layering UV white ink, The high speed UV printer creates a clear and stable micro-relief structure, which is then overlaid with color layers to achieve both visual 3D effects and tactile embossing on various materials such as glass, acrylic, metal, and PVC.

Breaking the limitations of material and shape, this UV cylinder printer is suitable for cylindrical and conical products such as water bottles, wine bottles, cosmetic tubes, fishing rods, and billiard cues. It supports printing on a wide range of materials including metal, glass, ceramic, plastic, and leather, meeting the needs of personalized and small-batch flexible production.

Uses high-quality, eco-friendly ink free of VOCs and harmful solvents, with nano-scale pigment particles for delicate and vibrant color. Once cured, the prints are scratch-resistant, UV-resistant, and corrosion-proof, maintaining their appearance both indoors and outdoors for a long time.

Offers 24-hour free sample printing and testing services, allowing customers to bring design files or physical samples for on-site experience. A professional technical team provides support, collaborating on innovative applications to help clients verify results and achieve efficient production.

Moonbox Cylinder/Round Bottle UV Printers, with their high speed, efficiency, and superior print quality, along with excellent adaptability to complex surfaces and various materials, provide a powerful solution for product decoration and personalized customization across a wide range of industries.

| Technical Parameters | |

| Equipment Dimensions | 1260MM*850MM*1850MM ( Length* Width * Height) |

| Equipment Weight | 350KG |

| Component Diameter | Standard base: 60–170mm, Optional: 10–60mm and 170–240mm |

| Taper/Drop | Taper: 0–8 degrees (length) Drop: 15mm |

| Printing Length | 40MM-300MM |

| Print Head Type | RICON G5I |

| Print speed | 30 seconds per piece, based on diameter 60mm×length 180mm, image CMYK |

| Printing precision | 900*1200 DPI |

| Ink type | UV ink, 4 colors + white + varnish |

| ink Configuration | BK、C、 M、Y、W ,V BK、C、 M、Y、W ,LC、 LM、V P、 BK、C、 M、Y、W ,LC、 LM、V |

| Software Support | RIP software |

| Graphic Format | TIFF, JPG, EPS, PDF, PNG, AI, PSD |

| Power Supply | 50HZ AC220/110±>10A Ground Wire Required |

| Environment | Temperature: 20–30°C | Humidity: 30%–60% |

| Application | All cylindrical, conical components, and container-type products |